Blog Detail

Blog Detail

- By Hafsa Aziz

Innovations That Have Changed Material Handling Equipment

Material handling has evolved with groundbreaking advancements that enhance efficiency, safety, and productivity in industrial operations around the world.

Manual vs. Automatic Tile Cutters: Which Is Best for You?

Deciding between manual and automatic tile cutters? Compare their features, efficiency, and ease of use to choose the right tool for precise tile cutting.

10 Common Pitfalls When Working With Natural Stone Materials

Prevent errors in natural stone projects and achieve flawless results and long-lasting pieces with the following advice on proper techniques and care.

Material handling has always been an essential part of industries like construction, fabrication, and landscaping. With constant demand for improved safety, greater efficiency, and better ways to manage heavy loads, this field has seen extraordinary developments over time. These days, equipment manufacturers are leaning heavily on technology and design to revolutionize how we move, lift, and transport materials.

Keep reading to know more about these 10 innovations that have changed material handling equipment. Here’s what’s shaping the future and making jobs simpler.

1. Vacuum Lifter Technology

The vacuum lifters of today are a game-changer, bringing unprecedented ease to transporting heavy and delicate materials like stone slabs and glass. Brands like Aardwolf have developed systems that use powerful suction to securely lift materials without damaging their surfaces.

For instance, the Aardwolf Vacuum Lifter boasts features like an acoustic alarm system for vacuum loss and a stainless-steel vacuum tank for added reliability. This innovation enhances safety and ensures precision, especially when moving high-value materials.

2. Ergonomic Seam Setters

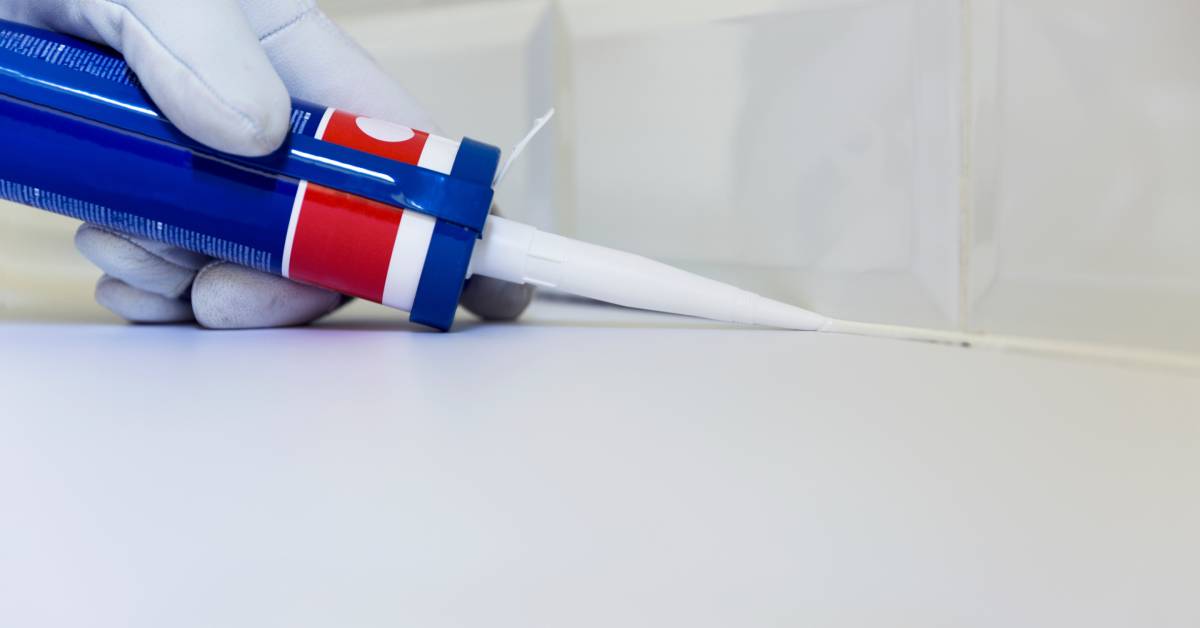

Gone are the days of manual laborers struggling to join countertops or slabs perfectly. Seam setters now come equipped with intelligent features like auto-leveling and pneumatic adjustment. The Omni Cubed PRO Stealth Seamer Auto is a prime example, designed specifically for perfect seam alignments in both residential and industrial settings.

These devices reduce worker fatigue and ensure flawless results, making them a must-have for any professional working with stone or tiles.

Best Use for Seam Setters

Seam setters excel in precision applications, such as joining granite countertops in luxury kitchens or aligning marble slabs in commercial projects. They provide accuracy and stability for flawless installations, especially with heavy materials, irregular surfaces, or tight deadlines. This helps professionals achieve seamless results efficiently without compromising quality.

3. Hydraulic Lifting Clamps

Hydraulic lifting clamps, such as the ABACO Little Giant Lifter, have changed how professionals handle stone slabs for the better. These automatic clamps adapt to the thickness of the material and securely grip loads, ensuring safe transportation and precise placement.

Their exceptional durability and versatility make them suitable for a wide range of applications, from heavy-duty construction projects to polished countertops, large paving slabs, and even intricate architectural designs.

4. AI-Driven Inventory Management for Racks and A-Frames

Managing inventory for material handling equipment often gets overlooked, but it’s critical to efficiency on the jobsite. AI-powered systems integrated into racks and A-frames offer real-time monitoring of load weights and storage conditions.

Take Groves’ Heavy-Duty Racks, for example. These sophisticated solutions allow for more organized storage, maximizing safety and workspace utilization. Not to mention, the durability and modular design make them extremely efficient for short-term and long-term use.

5. Suction Cups for Precision Handling

For delicate materials like marble or polished granite, innovative suction cups such as ZAK’s 8-inch suction cups have become essential. These tools provide superior control while allowing users to transport and position fragile materials with extreme precision.

Their high-grip rubberized surface is especially useful in providing a secure hold, significantly reducing the chances of accidental slipping or potential damage to your belongings.

Benefits of Using Suction Cups

Suction cups are a game-changer for professionals seeking efficiency and safety when handling delicate materials. They minimize the risk of scratches, chips, or cracks by ensuring a firm grip without damaging the surface. Their ergonomic designs reduce physical strain, making it easier to maneuver heavier and special materials with less effort.

6. Portable Gantry Cranes

Portable gantry cranes offer flexible, scalable lifting solutions for on-site or in-shop use. These cranes feature adjustable heights and lightweight aluminum designs, making them portable yet sturdy enough to handle heavy materials up to several tons.

Contractors who frequently need to relocate their workstations but still require reliable lifting capacity will find this solution highly appealing. It offers the perfect balance between mobility and performance, ensuring they can maintain efficiency without sacrificing functionality.

7. High-Tech Seamless Trolleys and Carts

When handling heavy slabs, mobility matters, and advanced material lifting equipment like Omni Cubed’s Pro-Cart AT1 shines brightly. With features like self-braking tires and adjustable carrying capacities, these carts make moving materials across uneven surfaces safer and easier.

The inclusion of shock-absorbent components further ensures stability and reduces the risk of damage, even when working with delicate, fragile, or high-value materials, providing peace of mind and added reliability.

8. Smart Material Detection Systems

Modern equipment has improved significantly through smart sensors that detect weight, density, and pressure. These tools offer precision previously hard to achieve. Devices like slab wedges are essential for accurate material alignment and leveling during installations, minimizing the risk of cracks, uneven surfaces, and costly errors.

By offering greater control over the installation process, these tools allow workers to achieve higher-quality results with less effort. This saves time and makes challenging tasks significantly more manageable for professional installers and shopfront workers, enhancing efficiency and overall project outcomes.

9. Advanced Manual Lifting Solutions

Even with advancements in automation, manual tools like hand clamps and A-frames have not gone obsolete. Instead, ergonomic redesigns now make them safer and less physically taxing. Tools such as the ABACO Stone Carrying Clamps use upgraded grips and materials that minimize wear and tear.

For instance, landscape and paver workers can easily transport those smaller slabs, while larger shop projects can benefit from the modularity of these handy tools.

10. Eco-Friendly Material Handling Equipment

Innovation isn’t just about efficiency; it’s also about sustainability. Equipment like reusable ZAK Protection Films offers environmentally friendly options for safeguarding counters and other materials during transit.

Similarly, many manufacturers have begun sourcing eco-friendly materials for equipment production, ensuring that sustainable practices remain at the core of material handling advancements.

What These Innovations Mean for You

The advancements in material lifting equipment and handling tools make the landscape, stone, and tile industries easier and safer than ever before. Professionals now have tools tailored for durability, precision, and handling, reducing jobsite risks and enhancing workplace productivity.

When discussing innovations that have changed material handling equipment, it’s amazing to see how technology has transformed traditional processes. Want to stay ahead of the curve in material handling? Browse through a wide selection of Aardwolf clamps, Groves racks, or seam setters today at Detroit Diamond Tools. Equip yourself with the latest tools for a smarter, safer work environment!