ALPHA HOT-ROD 3″ X 1/4″

$94.96

Product Features: ALPHA HOT-ROD 3″ X 1/4″

- Perfect for Channel Cutting with Wet/Dry Stone Cutter:

- Well-suited for channel cutting in stone fabrication.

- Versatility in usage with both wet and dry stone cutters.

- Great for Grout Removal with Ecocutter:

- Effective in grout removal when paired with an Ecocutter.

- Demonstrates adaptability to different tools and tasks in stone cutting.

- Fabricator’s Choice for Rodding on Granite:

- Preferred by fabricators for rodding on granite.

- Well-matched for reinforcing stone slabs with metal rods.

- Reliable Proven Performer:

- Emphasizes the tool’s reliability and proven performance.

- Instills confidence in users for consistent, satisfactory results.

- Can Be Used Wet or Dry:

- Adaptable to various working conditions, including wet and dry settings.

- Enhances overall utility for professionals in stone cutting and fabrication.

ALPHA HOT-ROD 3″ X 1/4″

Alpha® developed a revolutionary way to improve the efficiency of fabricators. For years, slab fabricators have employed labor-intensive procedures for creating channels in the underside of countertops to accommodate stainless steel reinforcing rods at sink and cooktop cutouts. Alpha® recognized the opportunity for improvement and developed the Alpha® Hot-Rod.

With this blade attached to the Alpha® AWS-110 or AWS-125 Wet Stone Cutter, a fabricator can accomplish the task in one easy pass. The Hot-Rod for Granite blades were created with diamond grits and matrix best suited for all categories of granite, including hard red granites, to assure a long cutting life.

With a 3” diameter, the blade allows for easy use and better leverage when cutting 1/4” deep channels, by allowing for better positioning of the stone cutter’s handle. This blade is now available in three thicknesses: 1/4” for standard rods, 1/8” for thinner rods, and 3/8” for threaded rods. The Hot-Rod for Marble applies the same technology but is designed for softer stones such as marble.

This blade is available in 1/4” for standard and 1/8” for thinner rods. For efficient creation of channels for reinforcing rods, attach this unique blade to our AWS-110 or AWS-125 for a smooth, dust-free operation. Used in this manner, productivity will increase significantly. Although Alpha® recommends wet cutting, these blades may be used wet or dry.

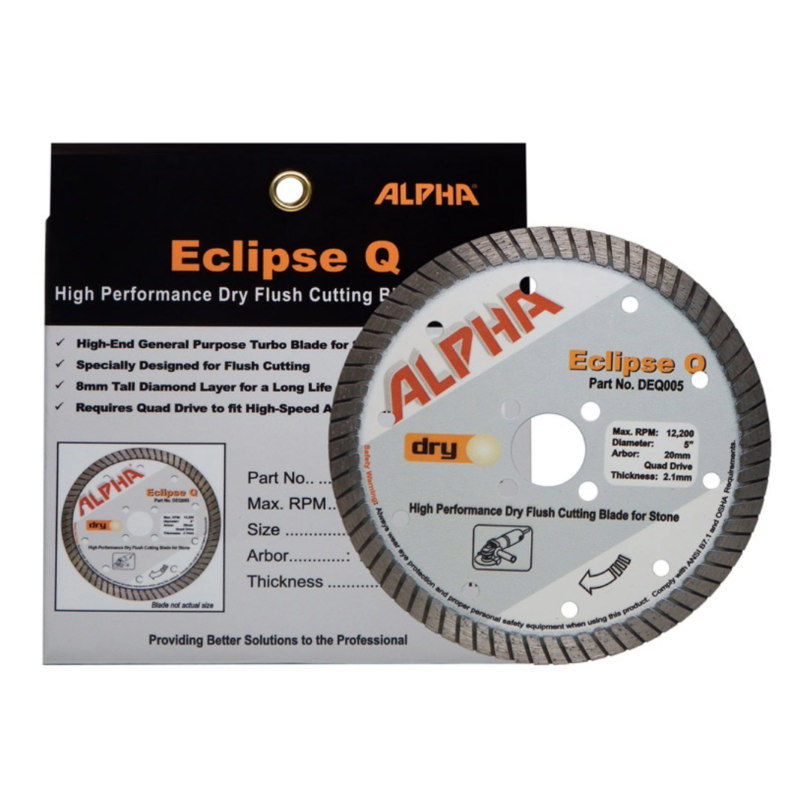

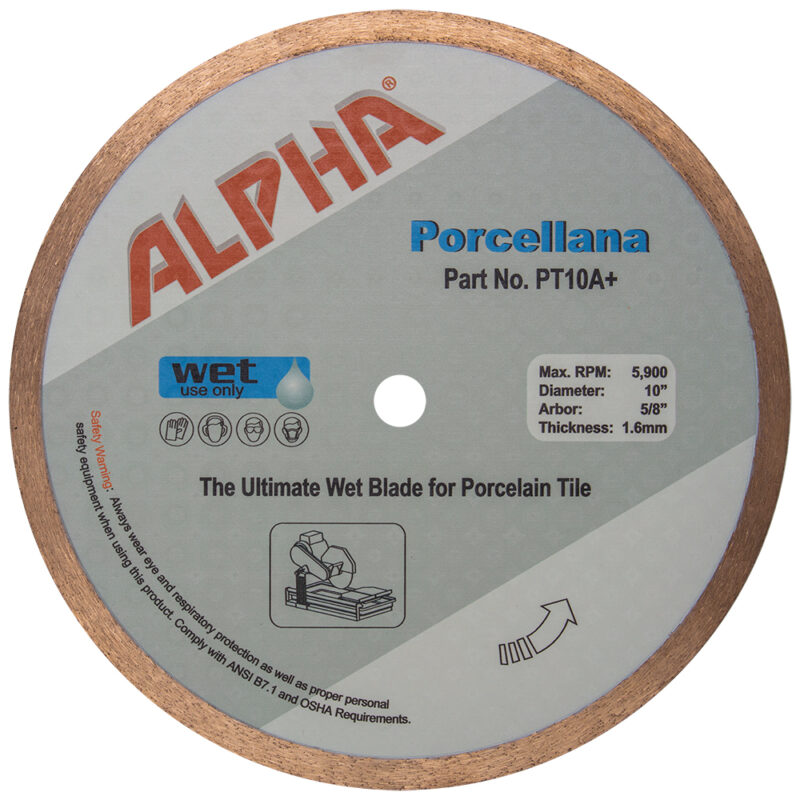

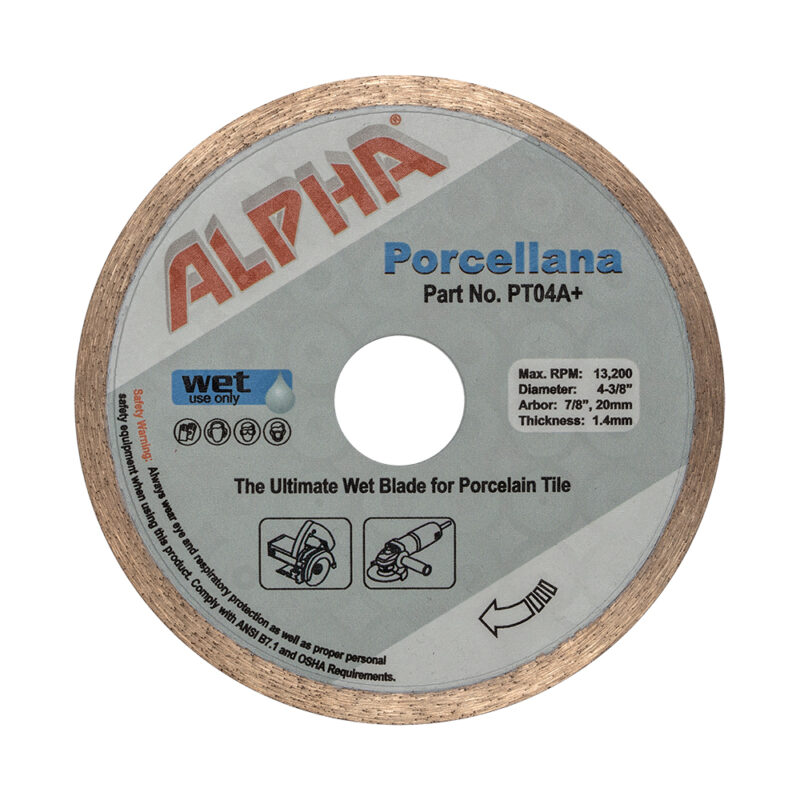

Related products

BMF™ ALL CUT PRO FLUSH CUT ELECTROPLATED BLADE W/ FLUSH MOUNT ADAPTER

-

- 4.5”

- 5"

- 6"

- Clear

NO DROPSHIPPING

We inventory products you see on our site

FREE SHIPPING ABOVE $250+

On all ground shipping Items

PRICE MATCH GUARANTEE

We'll beat the price from any competitor

FRIENDLY SUPPORT

Dedicated sales & support team

Everything you need in one place!

Company

Company

Support

Support

- Menu

- SUPPORT MENU