ABACO DEHYDRATOR

$8,400.00

Product Features of Abaco Dehydrator:

- Efficient Filtration System: Rapidly collects and traps abrasive mud and particles, ensuring clean water separation and minimizing waste.

- No Moving Parts: Designed for minimal maintenance with a simple, robust construction that reduces wear and tear.

- On-Site Dehydration: Processes mud and particles directly at the source, eliminating the need for secondary handling or transport.

- Haptic Components: Includes a pump, heating tank, clean water tray, and filter traps for comprehensive dehydration.

- High Heating Capacity: Features charged filter traps to maximize heating efficiency, ensuring effective moisture removal.

- Environmentally Friendly: Reduces environmental impact by efficiently managing waste and recycling clean water.

- Durable and Reliable: Built to withstand harsh industrial conditions, providing long-term performance with minimal downtime.

The ABACO Dehydrator (ADE089) tackles tough industrial filtration challenges with ease. This robust system handles abrasive mud, sludge, and wastewater efficiently right at your worksite. Built to last, it combines durable stainless steel construction with smart automation for reliable performance day after day.

Built Tough for Demanding Jobs

You’ll appreciate the ADE089’s corrosion-resistant stainless steel body that stands up to harsh conditions. Measuring 2433mm long × 700mm wide × 2330mm high and weighing 213kg, it fits neatly into your existing setup. The system works smoothly with its 2-inch brass valves and automatic float switches that take the guesswork out of operation.

Powerful Performance That Saves Time

What really sets this dehydrator apart is its ability to process 3 cubic meters of sludge per hour (at 25% concentration). The generously sized 350×1200mm filter bags catch abrasive particles effectively, while the built-in heating system speeds up drying. Best of all, the simple design with no moving parts means less maintenance and more uptime for you.

Where It Works Best

From mining operations to construction sites and water treatment plants, this dehydrator delivers consistent results where you need them most. It’s an environmentally smart choice too, as it helps recycle clean water while meeting industry regulations.

Why Customers Choose ADE089:

Processes sludge fast (3m³/hour capacity)

Built from long-lasting stainless steel

Automatic features reduce labor

Compact design saves space

Minimal maintenance required

Related products

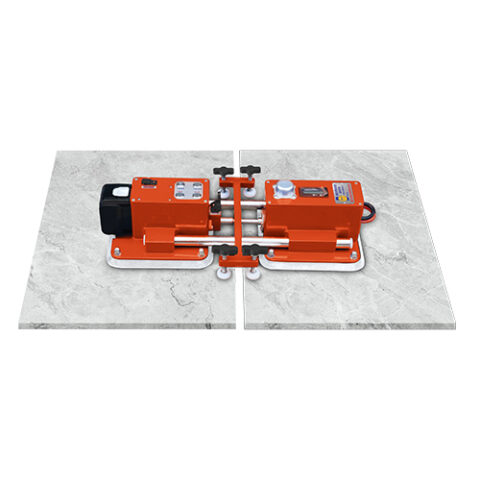

ABACO EZ-PRO BATTERY SEAM SETTER – AEBSS12V-M2

ABACO CABLE CONNECT SLING – ASL017

NO DROPSHIPPING

We inventory products you see on our site

FREE SHIPPING ABOVE $250+

On all ground shipping Items

PRICE MATCH GUARANTEE

We'll beat the price from any competitor

FRIENDLY SUPPORT

Dedicated sales & support team

Everything you need in one place!

Company

Company

Support

Support

- Menu

- SUPPORT MENU